New video: DynaPopeX

In the DynaPopeX project, TNO and Zicht op Data focus on reducing poor air quality. By combining data, location, and human movement patterns in Eindhoven, they develop tangible measures to minimize people’s exposure to harmful particulate matter and limit potential health risks. This is crucial for the municipality of Eindhoven to understand the most significant impacts of air quality and improve the health of its residents.

New project videos: Advanced piezo-electric wafer stage project

Keeping up with the demand for manufacturing growth is the main challenge for the entire semiconductor industry. The Eindhoven Engine OpenCall project ‘Advanced long-range piezo-electric wafer stage’ therefore aims to demonstrate the feasibility of an ultra-short stroke stage using lightweight and compact piezo-electric actuators.

Ron de Bruijn – PhD candidate TU/e

My research is about wafer stages that are driven by piezoelectric actuators. These actuators make a mechanical contact between the rest of the machine and the wafer stage. Minimal disturbance or vibration in the rest of the machine could actually affect a wafer position.

Gregor van Baars – Projectlead TU/e & Systems engineer TNO

ASML is extremely successful with their current technology. The question lies in how much room there is for expansion. This research begins from a completely different standpoint, offering significant advantages but also presenting numerous challenges.

New project videos: POWERLIFT

The OpenCall project Powerlift focuses on enhancing battery packs for unmanned aerial vehicles used in transportation, inspection, emergency services, and security. Through this project, the partners LeydenJar, Tulip Tech, and Wingtra aim to increase the deployment of drones in emergency situations, including organ transplantation, blood transport, professional assistance over long distances, and security purposes.

Battery technology for the future

At LeydenJar, we are working on battery technology for the future. At the moment our battery for a drone can store 70% more energy. Drones can now flying longer distances, lifting off with ease, and exploring more locations. Through our collaboration at Eindhoven Engine with Tulip Tech and Wingtra, we are creating a modular design that allows customizable battery capacity and power—whether it’s a compact pack or a robust one, tailored precisely to each drone’s requirements.

Battery systems with the highest energy density

In project PowerLift we, Leydenjar, Tulip Tech and Wingtra, develop battery systems for industrial drones. As a partner within this project Tulip Tech builds battery systems with the highest specific energy density in the world. That means that the batteries have two to three times more energy per kilogram.

Eindhoven Engine News – April 2024

In this edition of Eindhoven Engine News: From Unlikely to Unstoppable: Embracing Diversity in the Building Industry – a story from project partner Kropman & more!

What else is happening at Eindhoven Engine?

“I never saw myself working at Kropman,” Shalika Walker confesses. “And honestly, I might not have hired Shalika,” Joep van der Velden admits, seated beside her. “But how the OpenCall of Eindhoven Engine changed things. We’ve now created a new position within Kropman specifically to bring Shalika on board,” says Joep with a big smile.

We are at one of the offices of Kropman. This company designs, builds, maintains, and manages building installations, including climate control. “Kropman, rooted in construction, is traditionally less dynamic compared to sectors like semiconductors or the medical industry. So, working here was not on my radar,” Shalika shares.

Kropman’s Workspace: More Than Meets the Eye

“Welcome to our living lab,” Joep announces as he leads me into a spacious, open-plan office. At first glance, it looks ordinary, with dark gray carpets, white adjustable desks, and black office chairs. Joep notices my lukewarm reaction and gives a knowing sigh, directing my attention upward. “The real innovation is actually hidden above us in the ceiling.” I follow his gaze to a beige suspended ceiling, and he points out a translucent cap. “Those are sensors. They allow us to monitor and adapt the office environment, responding to the current scenario or the presence of workers.”

At Kropman, the pride lies in being system integrators. We source pumps from one company, sensors from another, and piping and operating systems from yet another. Our goal is to seamlessly blend these components, providing our customers with a unified operating system that manages lighting, climate control, and solar panels, among other things. This integration is meticulously crafted to enhance the experience for our clients’ employees, focusing on maximal efficiency and environmental sustainability, using as little energy as possible.

Embracing Open Collaboration for Innovation

Creating an integrated system might seem straightforward, but it’s a challenging endeavor. We’re in a field dominated by heavyweights like Siemens, Honeywell, and Signify, each offering products with proprietary systems and unique data outputs, typically closed to external systems. To navigate this, we developed our software to manage and optimize the diverse systems a client might have. However, the need for a testing ground became apparent. Clients often hesitate to open their buildings for experimental setups; hence, we transformed our Breda office into a living lab.

True partnership proved elusive until we found a more receptive community in the Brainport region.

We strongly believe in an open environment for research and development. Our efforts to collaborate with universities and companies across and beyond Europe, however have been met with limited success. True partnership proved elusive until we found a more receptive community in the Brainport region. This shares a work and research philosophy similar to our own company’s, plus communication is direct and efficient, enabling us to quickly and easily connect with each other. This welcoming atmosphere was pivotal when Wim Zeiler, a former colleague now with Eindhoven University of Technology and still an advisor at Kropman, introduced us to the Eindhoven Engine OpenCall. Recognizing its potential to foster meaningful partnerships, we eagerly seized this opportunity.

Eindhoven Engine’s OpenCall: A Catalyst for Collaboration

“Working with Eindhoven Engine offers a unique experience,” Shalika explains. “We share a location with a variety of companies and students, all engaged in their own projects. This diversity is beneficial. It’s not just about casual connections, like chatting at the coffee machine; we also attend sessions to share and discuss project progress.

For instance, while working on a data prediction project, I overheard a researcher at Eindhoven Engine’s Festival of Disruption event discussing data usage in cancer research. It didn’t click immediately, but later, the idea struck me at home: we could collaborate and enhance our respective research.

These interactions open up new perspectives and inspire innovative thinking. “This collaborative atmosphere was the reason Kropman signed up for three projects in a row. One project focused on detecting and diagnosing faults in building climate systems. The second project involved personalized thermal comfort systems, allowing employees to adjust their workspace climate via a smartphone app. The third was an assessment of CO2 sensors in the market, evaluating their accuracy for reliable CO2 readings in schools.

Although these projects are completed within Eindhoven Engine, we continue to build on the research and improve the products developed.” “And that’s why we brought Shalika on board,” says Joep.

Human-data interaction to enhance office well-being

Hi, my name is Hans Brombacher and I am a fourth year Industrial Design Ph.D. candidate. My work focuses on the topic of human-data interaction to enhance office well-being and is part of the POWEr FITTing project of Eindhoven Engine.

Three case studies

In the landscape of workplace technology, sensing systems play a crucial role in gathering data for understanding building performance and employee activities. However, a common challenge arises: individuals often feel disconnected from these systems, being treated merely as passive recipients of data. Three case studies propose practical solutions to address this issue.

Case 1. SensorBadge

Case 1 introduces SensorBadge, an ego-centric sensor platform allowing employees to actively participate in data collection and analysis. This approach emphasizes the importance of seamlessly integrating sensor technology into daily routines while ensuring individuals have control over their data. The study underscores the need for clear and understandable data representations to facilitate informed decision-making.

Case 3. Click-IO

Case 2. SensorBricks

Human-centered design

These case studies demonstrate the importance of human-centered design in workplace sensing technologies. By prioritizing user engagement, control, and understanding, these approaches pave the way for more meaningful insights and improved well-being in the modern workplace.

Integration of findings

Within our final study, which will start soon, we will integrate the findings of these studies into a unified artifact, prioritizing human-centric design principles. This aims to enhance data literacy, facilitate real-time feedback on well-being, and ensure employee control over data. Implementing such an ecosystem in diverse workplace settings could provide valuable insights into its effectiveness and ethical implications, ultimately fostering a more fulfilling and productive work environment.

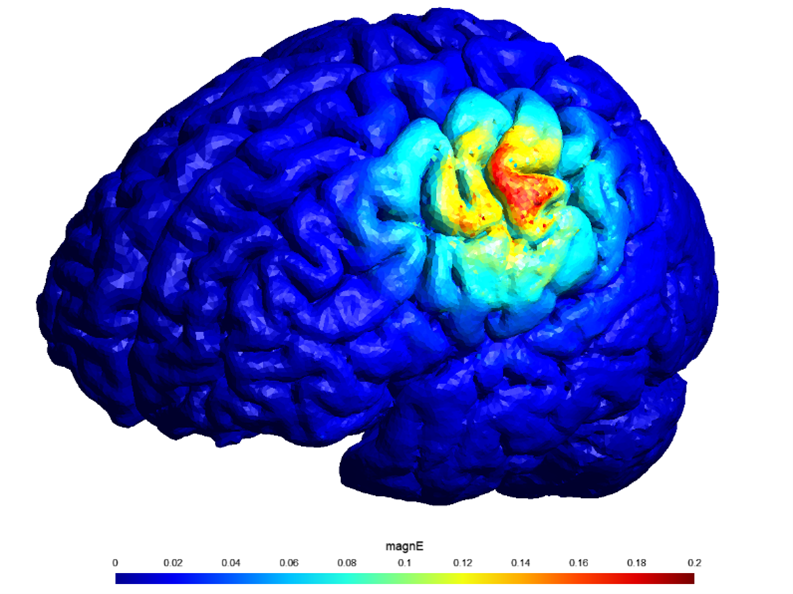

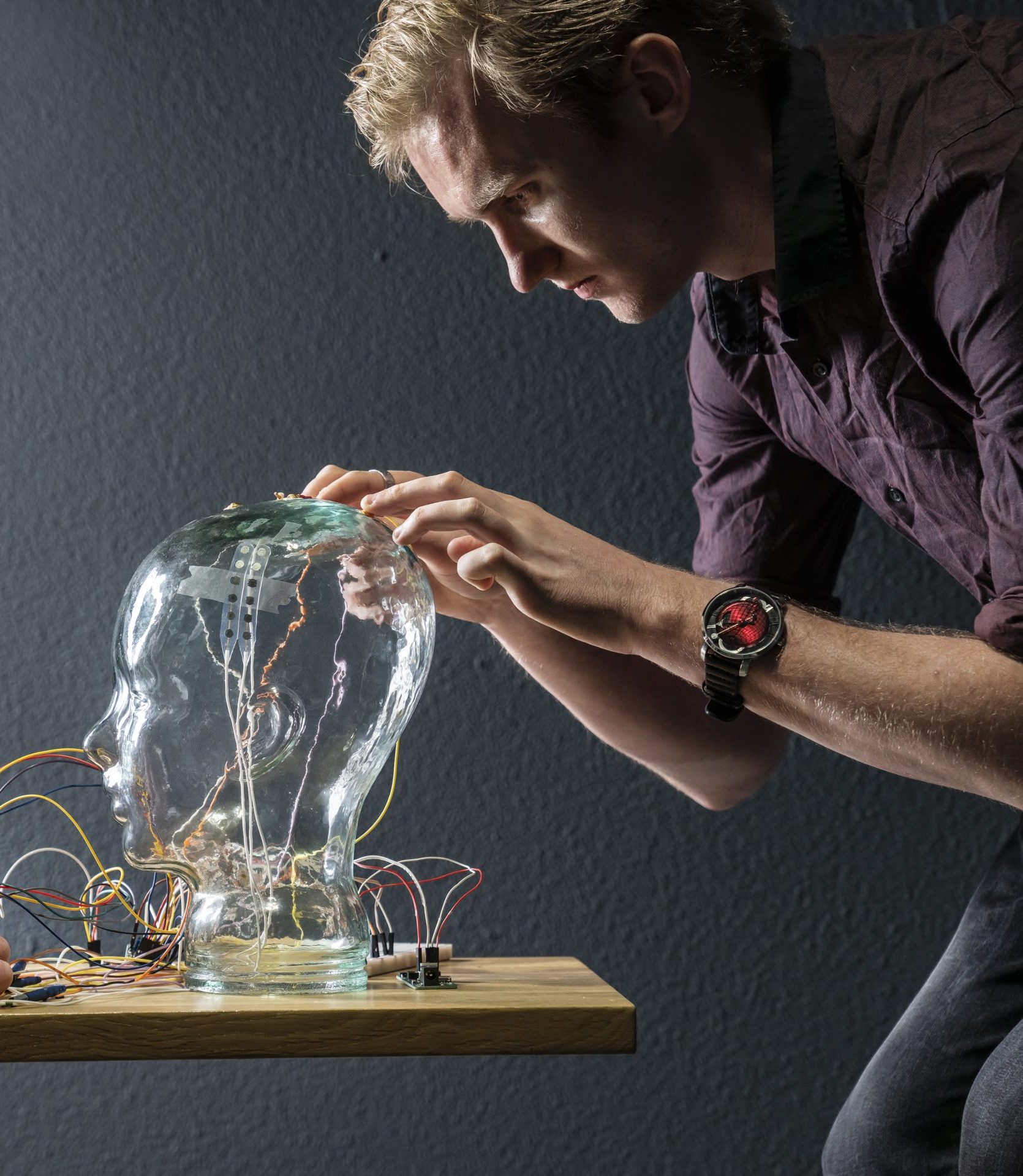

Empowering Epilepsy Care: Decoding Transcranial Electric Stimulation

Hi all, my name is Steven Beumer (30 years old) and for the last four years I’ve been doing my PhD at the TU/e, specifically the Electromagnetics group of Electrical Engineering. I was born and raised in Geldrop, a small village next to Eindhoven, so studying at this university was almost a no-brainer.

My research is focused on using transcranial electric stimulation for epilepsy patients that cannot be treated using medicine or surgery and is part of the PerStim project. This project was conceived from the wish to be able to reduce the treatment gap in epilepsy and thus lower the burden of this disease on the patients and society.

Electrical stimulation is simple, but very complex

Together with the Ghent University Hospital, Kempenhaeghe and Philips we started to research the use of electrical stimulation for epilepsy treatments. Through extensive literature studies, we found that the working mechanism of this technology is still poorly understood. Thus, we set out to answer a fundamental question using clinical studies: “Are we stimulating the brain with currents that go straight through the skull, or is it taking a more complicated route like the facial nerves?”

This method holds great promise for the future because of its affordability, simplicity, and potential for home use, which could ultimately reduce the need for frequent hospital visits.

To support these studies, I was tasked with making patient models, optimizing the electrode positions as well as analyzing the data. Together with students from Fontys and the TU/e, we built a full workflow to do this in a very quick and efficient manner. Eindhoven Engine enabled us to cooperate with the students from the Fontys. Their working mentality and different way of approaching problems were fundamental to significant parts of this work. Our clinical studies are still running, but preliminary results have shown that the answer to the abovementioned question might be that the stimulation works via both the direct and the indirect paths.

Looking into the future

Even though the use of transcranial electric stimulation is more complex than initially assumed, we have just started to unravel the actual working mechanism and I wholeheartedly believe that as we gain a deeper understanding, we can improve the methods and their efficacy. This method holds great promise for the future because of its affordability, simplicity, and potential for home use, which could ultimately reduce the need for frequent hospital visits.

My time at the university is running out, but I am still as fascinated by the world of brain stimulation as I was when starting this project and I’ll keep working in this field to improve the understanding of these techniques and unlock their potential for patients.

Media: ‘Slim schuurtje’ voorziet gebouwen het hele jaar door van energie (DUTCH)

Op de TU/e Campus in Eindhoven werken twee startups aan een nieuwe ontwikkeling die de energietransitie moet helpen versnellen. De startups combineren zogeheten warmtegevelpanelen met slimme energieopslag in de vorm van een berging; de zogeheten Smart Heat Shed.

Daardoor is bijvoorbeeld ook ‘s winters voldoende energie beschikbaar om een woning of kantoorpand te verwarmen. Om het systeem verder te verbeteren is een proefopstelling gebouwd op de TU/e Campus. Het project is één van 28 projecten van innovatieaccelerator Eindhoven Engine en is mede mogelijk gemaakt door Regio Deal Brainport Eindhoven.

Source: Brainport Eindhoven

New project videos: Carbyon 2.0

The atmospheric CO2 levels are excessively elevated, so urgent action is needed to lower them. Eindhoven Engine Project Carbyon is developping machines that are capable of capturing carbon from the surrounding air and filtering it out. The retrieved carbon dioxide can be either reused or securely stored for an indefinite period. By adopting this approach, Carbyon can effectively address the issue of climate change.

Into a working machine

Marco Arts is the chief operating officer at Carbyon. Currently, Carbyon is collaborating with Eindhoven University of Technology and DIFFER in the Eindhoven Engine project Carbyon 2.0 to verify their key technologies in their lab environments. Currently, they are developing a fully integrated working machine that takes in ambient air and delivers pure CO2.

Direct air capture by different solvents

Jasper Simons, CTO at Carbyon, showcases the first test version of their direct air capture equipment. And Shilpa Sonar is working as a postdoc researcher at Eindhoven University of Technology. Shilpa’s research is mainly focused on the direct air capture by the different solvents. Her research will be carried out in the Carbyon’s own home-produced reactor.

New project videos: Carbyon 2.0

The atmospheric CO2 levels are excessively elevated, so urgent action is needed to lower them. Eindhoven Engine Project Carbyon is developping machines that are capable of capturing carbon from the surrounding air and filtering it out. The retrieved carbon dioxide can be either reused or securely stored for an indefinite period. By adopting this approach, Carbyon can effectively address the issue of climate change.

Hans Krikhaar, who is leading this project and is a lecturer in Smart Manufacturing at Fontys Engineering, understood that SMEs have a great need for innovation, but lack the capacity and knowledge to do these innovations themselves. To be ahead of the competition, it is extremely important for SMEs to keep innovating their production processes. The industries need to adopt Smart Manufacturing. The fresh perspective and knowledge of Fontys students are the outcome here. In the ecosystem knowledge exchange at Eindhoven Engine makes cross-pollinations possible between Fontys students, SMEs, other companies and institutes. With the help of Eindhoven Engine, it results in a validated approach to strengthen the innovation power of SMEs in the Brainport region.

Projects in three focus areas

The goal of SmartMan project was to annually realize 40 subprojects carried out by 2nd, 3rd and 4th year Fontys students at SMEs. During the 3-year period at Eindhoven Engine, indeed a total of 120 projects at various companies were successfully completed. A very nice result considering this project withstood the corona epidemic. In the SmartMan project with Eindhoven Engine, Fontys, TNO and Brainport Industries as partners, students do their internship and graduation assignments in various facets of Smart Manufacturing.

These can be divided into three focus areas:

1. Topological design, which includes additive manufacturing and lightweight structures.

2. Intelligent systems (AI, low-code modeling and digital twinning).

3. Factory automation and robotics.

Knowledge exchange at Eindhoven Engine makes cross-pollinations possible between Fontys students, SMEs, other companies and institutes.

At VDL, successive students have worked on modular injection molds (topological design). In the area of intelligent systems, several students have used artificial intelligence for VBTI to further develop vision analysis, and at Siemens, students have collaborated on developing digital twins. Students have also contributed to factory automation solutions at various companies. At Eindhoven Engine project Carbyon DAC, a student even collaborated on the process plant for making CO2-absorbent material used to reduce CO2 in the atmosphere.

Stronger link

Fontys Engineering is working out plans to follow up on SmartMan. The goal is to link research even more closely to student projects in companies, especially in SMEs. Students will receive assignments within research domains at companies and teacher-researchers will provide the necessary knowledge transfer. This allows future students to complete their assignments more efficiently with the guidance and knowledge of the lecturer-researcher.