Podcast Kracht van de Regio

Eindhoven Engine

A podcast with Katja Pahnke and Maarten Steinbuch about how Eindhoven Engine accelerates innovation, including two projects. Marieke van Beurden will give you insight about the POWErFITTing project and Gregor van Baars will tell you about the Advanced piezo-electric wafer stage project.

This is part of a serie of podcasts about the Regiodeals in the Netherlands. Eindhoven Engine is part of the Brainport Regiodeal.

Dear Members,

We started this year with some really nice highlights, and we would like to share these with you. Although we are still working remotely, we have put a lot of effort into the Eindhoven Engine OpenCall 2021. On 3 February, we announced that the OpenCall 2021 is open. The opening of our co-location (MMP building) is another highlight. MMP is now ready to welcome our Eindhoven Engine community to collaborate, connect and get inspired! Let’s hope we can do this safely as soon as the COVID-19 measures allow.

In this edition, you can read an interview with Sonja Vos, CEO of TU/e Participations and TU/e shareholder of Eindhoven Engine. With this interview, we have completed our trilogy on sharing the views of Eindhoven Engine’s founders – TU/e, TNO and Fontys – on how to accelerate innovation in Eindhoven Engine and the need for agile innovation. Jaap Lombaers (TNO) and Ella Hueting (Fontys) gave their interviews in previous editions of the newsletter.

Today, the project in focus is SmartMan. Hans Krikhaar (Fontys project leader of SmartMan) and Kees Adriaanse (Fontys Liaison Officer at Eindhoven Engine and program leader of Fontys Centre of Expertise High-Tech Systems & Materials) explain the various aspects of smart manufacturing and collocative work by students on behalf of SMEs during this innovative project.

Also in this edition:

- ‘Isolation gowns’ innovation competition project selected for the RVO SBIR (Small Business Innovation Research)

- Eindhoven Engine project vacancies for students

- ‘Kracht van de Regio’ podcast: Eindhoven Engine as example of a RegioDeal project, discusses the successful formula of projects and their added value

- Eindhoven Engine Academy news: Business Model Innovation in an Exponential World by Walter Baets, Learning Officer Eindhoven Engine Academy

- Eindhoven Engine Community of Practice

- PDEng Design Challenge

Enjoy your read and become part of our community! Stay safe and healthy.

Katja Pahnke and Maarten Steinbuch

On 28 January 2021, the Netherlands Enterprise Agency (RVO) accepted Eindhoven Engine’s Small Business Innovation Research (SBIR) proposal on sustainable medical isolation gowns. Through SBIR, the government is challenging entrepreneurs to come up with innovative products and services to solve societal issues. Together with TNO and HAVEP, Eindhoven Engine submitted a proposal and we are proud to have been selected as one of the five projects. 10 proposals were submitted in total.

The fight against the COVID-19 virus is generating a lot of waste. The vast majority of protective materials used in the healthcare sector need to be destroyed after a single use due to the risk of contamination. In this research, Eindhoven Engine and its partners will focus on the development of sustainable medical isolation gowns that can be used multiple times: the ProH I-gown. In addition, an investigation will take place into how the production capacity can be made (economically) scalable and flexible when necessary.

These sustainable medical isolation gowns can save six tons of CO2 per million gowns. If these isolation gowns are fully utilized during crisis situations, the result could be a saving of 0.2% of the total plastic waste stream in the Netherlands. In addition, ProH Isolation gowns stimulate the production of protective clothing in Europe.

The execution of this research for the healthcare sector in the Netherlands consists of two phases. In this wonderful collaboration between innovation accelerator Eindhoven Engine, research organisation TNO and manufacturer HAVEP, a technical feasibility assessment will be carried out in the first phase. A business case will also be set up. The gowns will be made of woven PET material with an environmentally friendly coating. Research will also be carried out into the durability and wearability of these gowns. HAVEP will contribute its many years of knowledge and experience in the development and production of fabrics to this partnership. For this first phase, EUR 25,000 has been made available. In phase 2 of the project, the concrete industrialization will be worked out in detail. The official kick-off of this project is Tuesday 16 February 2021.

“I’m very happy with the start of this project: a large, relevant problem which we’re going to solve together!”

Maarten Steinbuch, Scientific Director Eindhoven Engine

How we work with partners from the industry, knowlegde institutions and students from Fontys and TU/e to accelerate innovation in the Brainport region.

“I have the nicest job in the Netherlands,” says Sonja Vos-Poppelaars. “As director of TU/e Participations, I represent TU/e as a shareholder of 54 companies, mainly start-ups. One of the participations is Eindhoven Engine, a joint venture from TU/e, Fontys and TNO.

Every day, it’s a delight to cooperate with inspired people who want to accomplish their dreams. The researchers are very smart, much smarter than I am. I like the fact that they are driven not by money but by an intrinsic motivation to innovate and create impact. As a representative from a stakeholder, I try to advise and challenge them with simple, provocative questions to keep them on track.”

Quick, result-driven work

Sonja started on her path at Nyenrode Business University and graduated as a Certified Public Accountant (CPA) on the subject of KPIs. “I simply love numbers. They don’t lie and are never vague. They help you to measure your performance.

That’s why I like to work with KPIs and that’s what I appreciate when I work for SMEs. These entrepreneurs want to work swiftly and are result-driven. I recognize this same attitude at Eindhoven Engine. This inspirational organization seeks to accelerate innovation by combining science, people from industry and students to create solutions with impact within a deadline.” A recent example is the artificial womb project. This started as fundamental research but, with the help of Eindhoven Engine, is now connected with two young entrepreneurs who in turn have involved students of business administration.

Sonja Vos

“Every day, it’s a delight to cooperate with inspired people who want to accomplish their dreams.”

Involve people to generate speed

“In my work with start-ups, I’ve noticed that the projects which involve and activate their network the most achieve their goals more effectively. That’s why I like the formula of Eindhoven Engine so much. They pull a team together from different backgrounds to work together on projects to solve social challenges or to create disruptive innovations.

They compose their teams of people from industry, SMEs, scientific staff from TU/e, TNO, Fontys and students of all kind of disciplines. This way, the team approaches the challenge from many different perspectives. And when these teams present their work across projects, it makes the formula even stronger. I have experienced this approach in smaller projects and know that it works.”

Respect, trust, openness

“In start-ups and R&D projects, it’s very important to create an environment of openness. There has to be trust and respect for each other. The pace of innovation is dependent on the freedom to speak your mind. Some critiques can be blunt. I know I can be blunt, but you have to be able to ask a relevant question or present an alternative view because beating around the bush takes up valuable time. That’s why it is so wonderful that we can operate in the Brainport region. It’s an informal network with very close ties and with the same attitude to constructive feedback. The mixture of three knowledge institutes alongside small and large companies, such as ASML, NXP, Signify and VDL, provides a unique ecosystem where innovation can accelerate.”

Translating basic research into meaningful solutions

“In this ecosystem, Eindhoven Engine is the perfect tool for projects to create breakthroughs.It fits perfectly with the main goal of TU/e: to translate basic research into meaningful solutions. We want to create responsible innovations and contribute to societal challenges in tight-knit collaborations with society and industry. That’s exactly what Eindhoven Engine does.”

“In this ecosystem, Eindhoven Engine is the perfect tool for projects to create breakthrough.”

Goal monitoring

“When Eindhoven Engine was initiated by TU/e in 2018, I assisted them in developing a financial model and put the governance in place. Since the end of the initial phase, my role as stakeholder has decreased, as it should. Now that the foundation is in place, I follow them from a distance. Together with co-shareholders Fontys and TNO, we are monitoring the strategic goals.”

Treasure the fun

“What advice would I give Eindhoven Engine right now? Keep involving as many complementary people in your projects as possible. The combination of TU/e, Fontys and TNO, together with the strengths of Brainport’s industry and the willingness to cooperate, creates an excellent, fertile ground for overcoming societal challenges. I’ve found that I work best with people from different walks of life who possess complimentary skills and also . . . simply have fun. A lot of start-ups begin with team members who are friends. There is a lot of excitement and plain fun, and this contributes to the speed and success of their endeavor. So, whatever you do, treasure the fun!”

We’ve kicked off! With a small group, Joris Dufils held our first community get-together to lay the basis for our Community of Practice.

This community will become an important instrument to accelerate innovation at Eindhoven Engine. We shared our passion for radical innovation and talked about how this community could provide high value to our projects and members without losing its organic, spontaneous and informal nature and culture. It was awesome to experience the common need for this community, such as simply meeting and getting to know each other. For some, this meant a place to cope with the boredom and loneliness of working at home. But it was also an opportunity to share best practices and find common interests and topics to discuss with (and inspire) peers and people from different backgrounds, domains or businesses.

We’re gaining momentum while growing our community and we need you to keep this up! We’re excited to welcome you to the next (virtual) get-together! Interested? Drop us a message!

In 2020, Kadans Science Partner took on the renovation of the MMP building on the TU/e Campus. Last Thursday the renewed MMP was officially opened through a live streamed event.

Because of the current situation we live in, a physical opening event was obviously out of the question. To give the renovation of MMP and its official re-opening the attention it deserves, a digital event was organized to give everyone more insight into the renewed location. The event was streamed live from the new restaurant in MMP. Host Rudy van Beurden welcomed special guests Michel Leemhuis (CEO Kadans Science Partner), Bert Pauli (Chairman of the Supervisory Board Eindhoven Engine), Robert Jan Smits (President of the Executive Board TU/e), Stijn Steenbakkers (Councillor for Economy, Brainport, Education, Innovation and Sport at the Municipality of Eindhoven) and Paul van Nunen (Director Brainport).

Open character

The dated interior of the building has been updated and comfort and sustainability have been increased. The new open character of MMP stimulates users of the building to interact with each other and to strengthen knowledge exchange. New ideas often start during social interactions at the coffee corner. “We realized we needed to do more than just offer space. We need to create an environment where our tenants can be optimally successful. This is why we added additional services for our tenants, such as social and scientific events where people can meet so collaborations can be established”, said Michel Leemhuis on behalf of Kadans.

Eindhoven Engine one of the main users

One of the main users of MMP is Eindhoven Engine, co-locating various projects at the location. “We bring together knowledge of the Eindhoven University of Technology, Fontys University of Applied Sciences and TNO, and together with the companies here we set up new projects for the market” said Bert Pauli, Chairman of the Supervisory Board of Eindhoven Engine. “Here we can meet other people that are also willing to set up new projects. Here they all come together: scientists, students, professors, entrepreneurs and investors. This is how we do it here in Brainport: open innovation.”

Support high-tech start-ups

MMP is specifically aimed at supporting various high-tech start-ups. “The Eindhoven University of Technology is the biggest provider of start-ups in the Brainport region. Start-ups need to be facilitated and supported, which means providing affordable accommodation but also providing all the other services from property rights all the way to access to venture capital and mentors and coaches,” added Robert Jan Smits, President of the Executive Board of the TU/e. “You feel welcome when you enter the building so I think a lot of start-ups will find their home in this building.”

The municipality even hired a start-up officer to connect all the questions start-ups have to the developments in the city. Both Stijn Steenbakkers (Councillor for the Municipality of Eindhoven) and Paul van Nunen (Director Brainport) elaborated on the importance of stimulating entrepreneurship within the Brainport region. They suggest start-ups get in touch with both Eindhoven Engine and the start-up officer as well as to just contact other interesting companies to connect. “The ecosystem around high-tech, start-ups and large companies and the University of Technology is unique and I believe that’s where our true value is, not only for this region but for the Netherlands in the future,” said Stijn Steenbakkers.

The building was officially opened with contribution from one of the start-ups accommodated in MMP: the autonomous car from AIIM ‘cut’ the ribbon to declare the building re-opened.

Source & photos: Kadans Science Partner

As an Eindhoven Engine stakeholder, Fontys University of Applied Science has a vital role to play in connecting innovative minds. In the SmartMan project, this centers on the intersection of students and small to medium-sized enterprises (SMEs), as Fontys colleagues Hans Krikhaar and Kees Adriaanse explain.

Passing the baton

“I always thought that when you get older, you should stop the career rat race and transmit your knowledge to young people. That’s the reason I started at Fontys,” begins Hans, Professor of Smart Manufacturing and project leader of SmartMan. “All of our students do projects in industry. By introducing new ideas to these projects, we help industry to improve.”

“All of our students do projects in industry. By introducing new ideas to these projects, we help industry to improve.”

Kees Adriaanse

This manifests itself in SmartMan, which investigates various aspects of smart manufacturing and executes student projects at SMEs. Since the project’s start in September 2020, two topics have evolved internally: quick response manufacturing and additive manufacturing & topological design. The former focuses on aspects like logistics and bottlenecks while the latter enables durable, lightweight structures with less material requirements.

Step by step

Eindhoven Engine’s goal of accelerating innovation requires collaboration; collaboration often requires a community. And as Kees notes, the ideal community connects all links of the chain for maximum impact. “Universities mostly work with fundamental research at TRLs 1, 2 and 3, but Fontys is working more at 4 to 7. Fontys is more connected to SMEs than universities. When Fontys and the university work together, Eindhoven Engine’s scope is broader.”

“With our students, we can implement step-by-step processes.”

Hans Krikhaar

Aligning itself with the agendas of both Brabant and Brainport, SmartMan is thus building a community of SMEs with an uncharacteristically high focus on innovation. “The return on investment for SMEs needs to be quick because they don’t have large budgets,” says Hans. “With our students, we can implement step-by-step processes. If each small step brings them economic benefits, they’ll do the next one.”

A fresh set of eyes

Although physical meetings have taken a hit during the COVID-19 pandemic, plans have now been made for a SmartMan co-location in the MMP building. For Kees, this is an excellent step for both Fontys and the Engine. “In the Centre of Expertise HTSM, we’re used to connecting companies and research groups. There are almost 6000 companies in the HTSM sector in this region and I hope that they find a way to innovate with us.”

“We will co-locate because to form a community, you need a place to be,” adds Hans. “But many of the activities will take place at the location of the company. On location, companies have gotten used to their daily worries and don’t see them anymore. If somebody looks at the production process with fresh eyes, he or she will find things to improve. A student thinks outside the box because a student is not yet in a box.”

Kees nods his head. “A student has the disadvantage that he’s young and the advantage that he’s young.”

SmartMan partners:

TNO, VDL, VBTI and:

Bodec, Cordis, Siemens, Alten, K3D, Brom, HAN, TSG, Hoppenbrouwers, Contour, TU/e, VDL projects, Inther, Vincitech, CMS, Wemo, Alten, Siemens, Alumero, VDL-ETG/ MTA/, Nexperia, ASML, Prodrive/ Neways, MI Partners, IBS Precision, VDL-Fibertech

Watch here the digital re-opening of MMP. Discover what stakeholders Gemeente Eindhoven & Brainport Eindhoven and tenants EIRES – Eindhoven Institute for Renewable Energy Systems & Eindhoven Engine say about the added value of MMP for Brainport.

In an intense last week of January, teams of PDEng trainees worked on challenges presented to them by companies. One of the challenges which a team worked on was the ‘Future of Work’ demo project of Eindhoven Engine.

Future of work

The challenge we gave them was as follows. Hybrid forms of (remote) working have an impact on communication, connection and creativity in teams (at the very least) – an impact that we are beginning to understand. However, our reflection should have started earlier. What is the purpose of work? Can we create an environment and approach that moves away from linear, predetermined thinking and opens doors to more creativity and eventually more fun? Can we use this opportunity to start working ‘smarter’, not just doing the same with smarter technology? Can we use tools that facilitate efficient ways of working, such that we do not have to adapt to existing procedures and platforms but instead redesign processes and support tools in alignment with one another? How can we create accidental meetings in a virtual environment, the chaotic situation that invites us to reinvent ourselves?

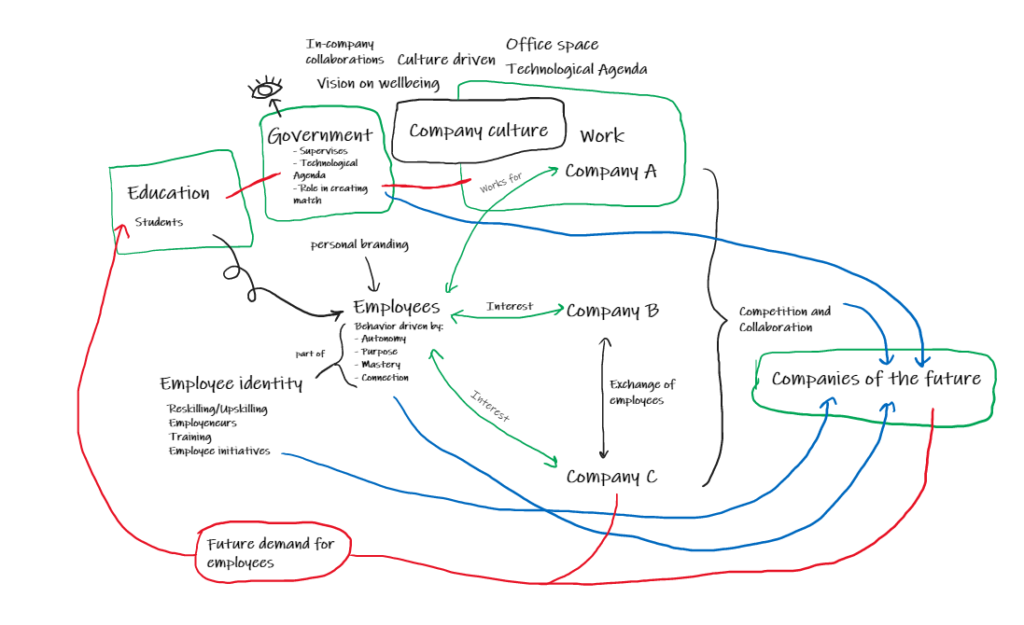

The team came up with some interesting ideas that we are going to take further when we define our demo project on the Future of Work. They constructed a causal loop diagram, from which they developed two possible interesting scenarios: working smart instead of hard (with creative jobs and a focus on the human dimension of work) and work as a learning process (lifelong learning, upskilling/reskilling, use of learning machines to support this match between work/learning). The team observed a tendency to move away from ‘learning in order to work’ towards ‘working in order to learn’. This focus also has huge potential in helping to define University 4.0. Eventually, they also paid attention to the ‘network employee’: the (knowledge) worker who works for different projects and no longer for a company.

Lots to think through in relation to these highly creative, challenging ideas which are at the center of what corporates are being confronted with. The next step is a pilot project in order to work further on detailing these possible scenarios, after which Eindhoven Engine will launch the Future of Work as a supported demo project.

For more information, please contact Walter Baets, Eindhoven Engine Academy