New video: DynaPopeX

In the DynaPopeX project, TNO and Zicht op Data focus on reducing poor air quality. By combining data, location, and human movement patterns in Eindhoven, they develop tangible measures to minimize people’s exposure to harmful particulate matter and limit potential health risks. This is crucial for the municipality of Eindhoven to understand the most significant impacts of air quality and improve the health of its residents.

Media: Innovation accelerator Eindhoven Engine enters new phase

Technology with a clear social purpose an starting with the problem.

As a society, we face numerous challenges. At Eindhoven Engine, a collaborative program between companies, knowledge institutions, social organizations and citizens in the Brainport region, work has been going on for years on innovations to address these problems. Now the program is breaking new ground.

Source: Eindhoven University of Technology

Media: Technologie met een duidelijk maatschappelijk doel:

[Dutch]

Innovatieversneller Eindhoven Engine gaat nieuwe fase in

Als maatschappij staan we voor talloze uitdagingen. Bij Eindhoven Engine, een samenwerkingsprogramma tussen bedrijven, kennisinstellingen, maatschappelijke organisaties en burgers in de Brainportregio, wordt er al jaren gewerkt aan innovaties om deze problemen het hoofd te bieden. Nu slaat het programma een nieuwe weg in.

Source: Innovation Origins

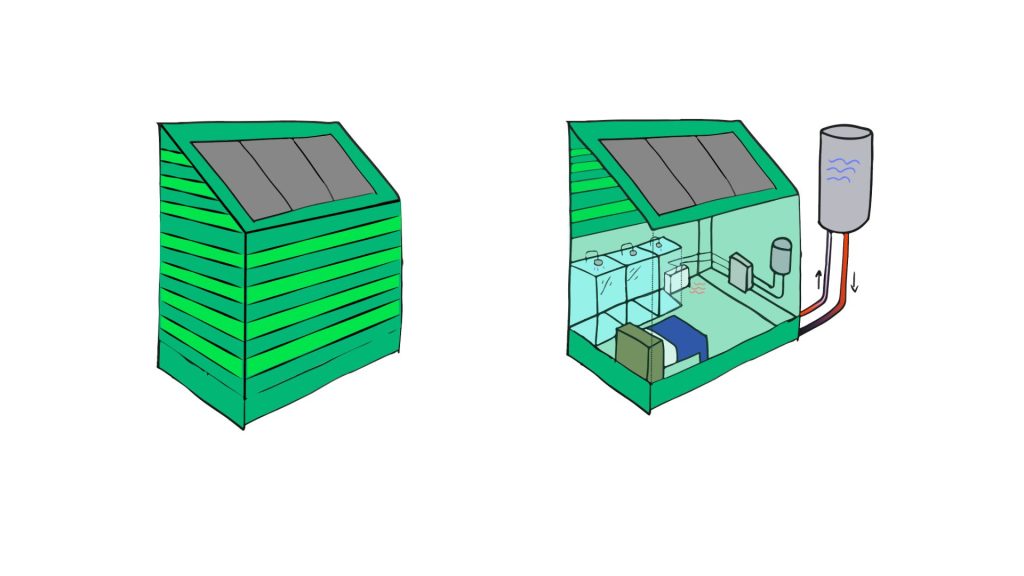

The Smart Heat Shed, but different

Hi, my name is Jamy de Lange. I am 21 years old, and I am currently finalizing my third year of my bachelor’s degree in Business Innovation.

At the end 2023 I worked on an OpenCall project with TNO and Emergo called the Smart Heat Shed (SHS). The SHS is an innovative storage facility that houses an installation for heating and cooling buildings. My challenge was make the SHS suitable for the housing corporations, so that it could be installed for many houses.

Getting started

The first step was to get a better understanding of de SHS by doing research. On the basis of these insights I was able to make questions for the housing corporations that were were already testing the SHS in practice (at a small scale), which is why I wanted to know about their experiences. The insight I gained from the interviews showed me that there was still some work to do to get de SHS suitable for the housing corporations.

After obtaining insights from my research I organized brainstorm sessions that were focused on the feedback from the housing corporations. I even wanted to try, if possible to use the SHS outside of the housing market (which is totally different than the purpose of which it is built). The results of this made me start to think about an interesting solution. Something that would bring music to everybody’s ears…

New insight

The concept I came up with is focused on applying the SHS to festivals. Further research revealed that some festivals use generators, consuming significant amounts of diesel. Lowlands, for example uses 120,000 liters of diesel to generate electricity. This is why I was certain I had to delve deeper in this direction.

“Some festivals use generators, consuming significant amounts of diesel. Lowlands for example uses 120,000 liters of diesel to generate electricity.”

Smart Heat Shelter prototype

First I came in contact with a stakeholder at Emergo, just to make sure that my concept would be interesting for them. An enthusiastic reaction prompted me to focus on this concept. Later, I send an email to Lowlands, which, to my surprise, was submitted to the director. He provided feedback that gave me insight on adapting the concept for general application to festivals.

The Smart Heat Shelter

After the positive reactions I adjusted the concept based on the feedback given. After this step I tested it again until I had formed my final concept (see prototype picture). I am proud to present to you: The Smart Heat Shelter. This concept allows festivals to lease a certain number of sheds, which can be placed at an available spot. Once installed, the sheds use sunlight to produce heat, which can be used for showers or to heat the sheds when used as accommodation. . The sheds are in different varieties for guests to enjoy different types of stay.

Recently, I engaged with numerous specialists across different sectors, seeking guidance from a business mentor and consulting professionals in eco-friendly (residential) building. Through these discussions, I’m refining my concept to make sure it’s ready for the marketplace.

Should you have any inquiries or suggestions after perusing this article, don’t hesitate to email me at: j.d.lange2@tue.nl

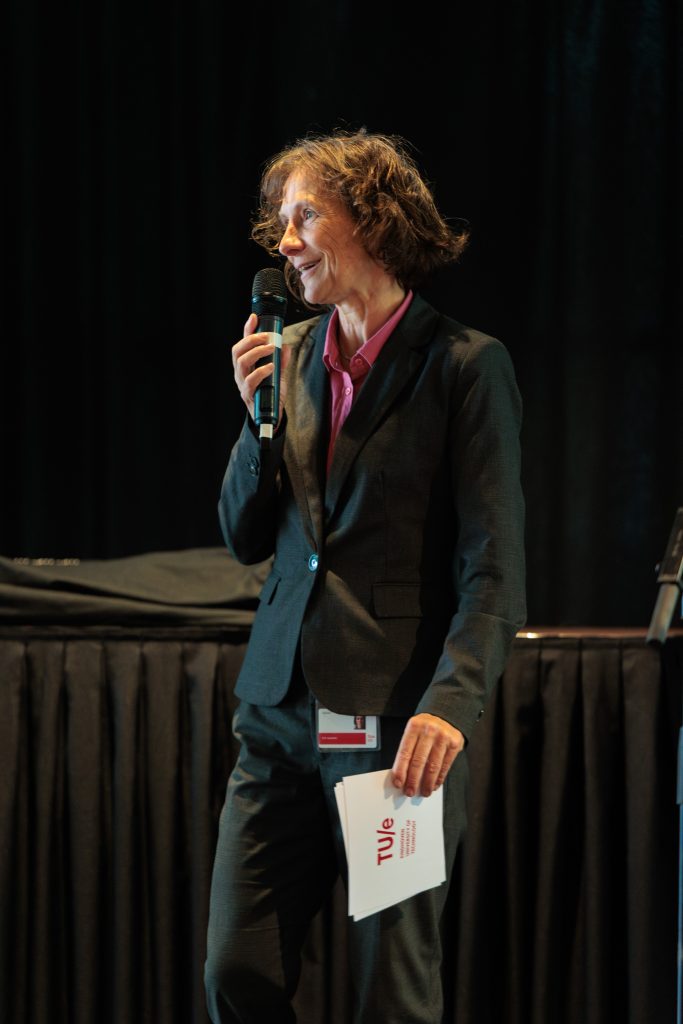

Celebrating five years of Eindhoven Engine

We had an incredible time celebrating our five year milestone, surrounded by great company and reflecting on our journey. From our ambitious beginnings to our impactful present. The celebration kicked off with an inspiring speech by TU/e Rector Magnificus Silvia Lenaerts, highlighting the importance of valorization, the strength of our partnerships, and our commitment to addressing societal challenges.

A special treat was the stunning musical performance by the talented artists from Impressariaat Kunsten van Fontys, adding a perfect touch to our celebration.

Human-data interaction to enhance office well-being

Hi, my name is Hans Brombacher and I am a fourth year Industrial Design Ph.D. candidate. My work focuses on the topic of human-data interaction to enhance office well-being and is part of the POWEr FITTing project of Eindhoven Engine.

Three case studies

In the landscape of workplace technology, sensing systems play a crucial role in gathering data for understanding building performance and employee activities. However, a common challenge arises: individuals often feel disconnected from these systems, being treated merely as passive recipients of data. Three case studies propose practical solutions to address this issue.

Case 1. SensorBadge

Case 1 introduces SensorBadge, an ego-centric sensor platform allowing employees to actively participate in data collection and analysis. This approach emphasizes the importance of seamlessly integrating sensor technology into daily routines while ensuring individuals have control over their data. The study underscores the need for clear and understandable data representations to facilitate informed decision-making.

Case 3. Click-IO

Case 2. SensorBricks

Human-centered design

These case studies demonstrate the importance of human-centered design in workplace sensing technologies. By prioritizing user engagement, control, and understanding, these approaches pave the way for more meaningful insights and improved well-being in the modern workplace.

Integration of findings

Within our final study, which will start soon, we will integrate the findings of these studies into a unified artifact, prioritizing human-centric design principles. This aims to enhance data literacy, facilitate real-time feedback on well-being, and ensure employee control over data. Implementing such an ecosystem in diverse workplace settings could provide valuable insights into its effectiveness and ethical implications, ultimately fostering a more fulfilling and productive work environment.

Join us in celebrating 5 years of Eindhoven Engine!

During our birthday party, we’ll share the milestones, successes, and challenges we’ve experienced within the organization and our projects. Come and join the festivities. It promises an afternoon of celebration, where we’ll introduce our next steps as we transition from technology push to society pull, offering an opportunity to embrace disruption.

We look forward to your arrival and toasting together to our anniversary.

See you on May 29th!

Media: ‘Slim schuurtje’ voorziet gebouwen het hele jaar door van energie (DUTCH)

Op de TU/e Campus in Eindhoven werken twee startups aan een nieuwe ontwikkeling die de energietransitie moet helpen versnellen. De startups combineren zogeheten warmtegevelpanelen met slimme energieopslag in de vorm van een berging; de zogeheten Smart Heat Shed.

Daardoor is bijvoorbeeld ook ‘s winters voldoende energie beschikbaar om een woning of kantoorpand te verwarmen. Om het systeem verder te verbeteren is een proefopstelling gebouwd op de TU/e Campus. Het project is één van 28 projecten van innovatieaccelerator Eindhoven Engine en is mede mogelijk gemaakt door Regio Deal Brainport Eindhoven.

Source: Brainport Eindhoven

Festival of Disruption filled with energy and enthusiasm

The Festival of Disruption’s second edition thrived with energy and enthusiasm. Kicking off the day, architect and urban designer Floris Alkemade offered a compelling perspective on how to embrace transformative changes.

Engaging workshops

Following this inspiring start, attendees were presented with seven engaging workshops, each delving into methods to expedite innovation, including ‘Design doing’, ‘Accelerating transitions via disruption’ and ‘1+1=3.’ Moreover, they had the chance to stay up to date on the latest developments in Eindhoven Engine’s OpenCall projects and the Emergence Lab initiative focusing on low literacy. As the day drew to a close, the atmosphere was charged with excitement during the wrap-up quiz, concluding a day, filled with learning, inspiration, and networking.

Did you miss out on the festival or do you want to relive the day? Get an impression of it here!

Possible continuation for SmartMan project at Fontys

The SmartMan project at Eindhoven Engine is approaching its end date. SmartMan is an OpenCall project that started in 2020 and has a duration of three years. This summer, the project ends at Eindhoven Engine, but is working on a follow-up at Fontys Engineering.

Hans Krikhaar, who is leading this project and is a lecturer in Smart Manufacturing at Fontys Engineering, understood that SMEs have a great need for innovation, but lack the capacity and knowledge to do these innovations themselves. To be ahead of the competition, it is extremely important for SMEs to keep innovating their production processes. The industries need to adopt Smart Manufacturing. The fresh perspective and knowledge of Fontys students are the outcome here. In the ecosystem knowledge exchange at Eindhoven Engine makes cross-pollinations possible between Fontys students, SMEs, other companies and institutes. With the help of Eindhoven Engine, it results in a validated approach to strengthen the innovation power of SMEs in the Brainport region.

Projects in three focus areas

The goal of SmartMan project was to annually realize 40 subprojects carried out by 2nd, 3rd and 4th year Fontys students at SMEs. During the 3-year period at Eindhoven Engine, indeed a total of 120 projects at various companies were successfully completed. A very nice result considering this project withstood the corona epidemic. In the SmartMan project with Eindhoven Engine, Fontys, TNO and Brainport Industries as partners, students do their internship and graduation assignments in various facets of Smart Manufacturing.

These can be divided into three focus areas:

1. Topological design, which includes additive manufacturing and lightweight structures.

2. Intelligent systems (AI, low-code modeling and digital twinning).

3. Factory automation and robotics.

Knowledge exchange at Eindhoven Engine makes cross-pollinations possible between Fontys students, SMEs, other companies and institutes.

At VDL, successive students have worked on modular injection molds (topological design). In the area of intelligent systems, several students have used artificial intelligence for VBTI to further develop vision analysis, and at Siemens, students have collaborated on developing digital twins. Students have also contributed to factory automation solutions at various companies. At Eindhoven Engine project Carbyon DAC, a student even collaborated on the process plant for making CO2-absorbent material used to reduce CO2 in the atmosphere.

Stronger link

Fontys Engineering is working out plans to follow up on SmartMan. The goal is to link research even more closely to student projects in companies, especially in SMEs. Students will receive assignments within research domains at companies and teacher-researchers will provide the necessary knowledge transfer. This allows future students to complete their assignments more efficiently with the guidance and knowledge of the lecturer-researcher.