About the project

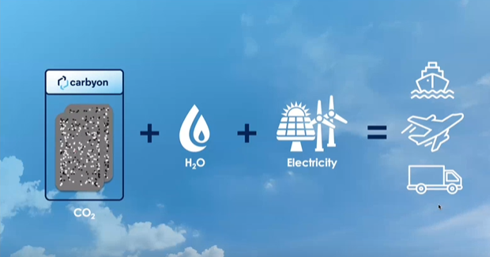

Carbyon is developing technology to capture CO2 directly from ambient air (Direct Air Capture, DAC). The captured CO2 can be converted into a renewable carbon source in various ways. Net-zero solutions are made possible by using this CO2 in processes and products, such as in greenhouses to improve crop growth or for the production of renewable synthetic fuels (e.g., for aviation). Net-zero solutions involve the permanent storage of CO2 underground, for example in depleted gas fields.

During the previous Eindhoven Engine project (OpenCall 2020), Carbyon achieved breakthrough results in proving the working principles of the key components of Carbyon’s DAC solution. The current project (OpenCall 2022) aims to further develop this innovative technology and its key factors on an industrial scale.

Video

The atmospheric CO2 levels are excessively elevated, so urgent action is needed to lower them. Eindhoven Engine Project Carbyon is developing machines that are capable of capturing carbon from the surrounding air and filtering it out.

Marco Arts – Chief Operating Officer Carbyon

The retrieved carbon dioxide can be either reused or securely stored for an indefinite period. By adopting this approach, Carbyon can effectively address the issue of climate change.

Jasper Simons – Chief Technology Officer Carbyon | Shilpa Sona – Postdoc TU/e

Jasper Simons, CTO at Carbyon, showcases the first test version of their direct air capture equipment. Shilpa Sonar is working as a postdoc researcher at Eindhoven University of Technology and her research is mainly focused on the direct air capture by the different solvents.

About the project

Unlocking mechanical limitations of synthetic heart stents with auxetic, fiber tubular scaffolds.

In the fight against cardiovascular disease, stents and grafts are implanted in patients to support or repair damaged or high-risk vessels. These stents and grafts provide robust mechanical support, but do not provide tissue repair. It would be better if such implants actively promoted tissue repair and regeneration over time.

The AUXSTENT project addresses these challenges and is already working on 3D-printable and bioresorbable stents that encourage and stimulate regeneration. At Eindhoven Engine, AUXSTENT will take the next step: developing a functional prototype. In this project, the focus is on combining the functional design of these stents with available engineering and materials knowledge.

About the project

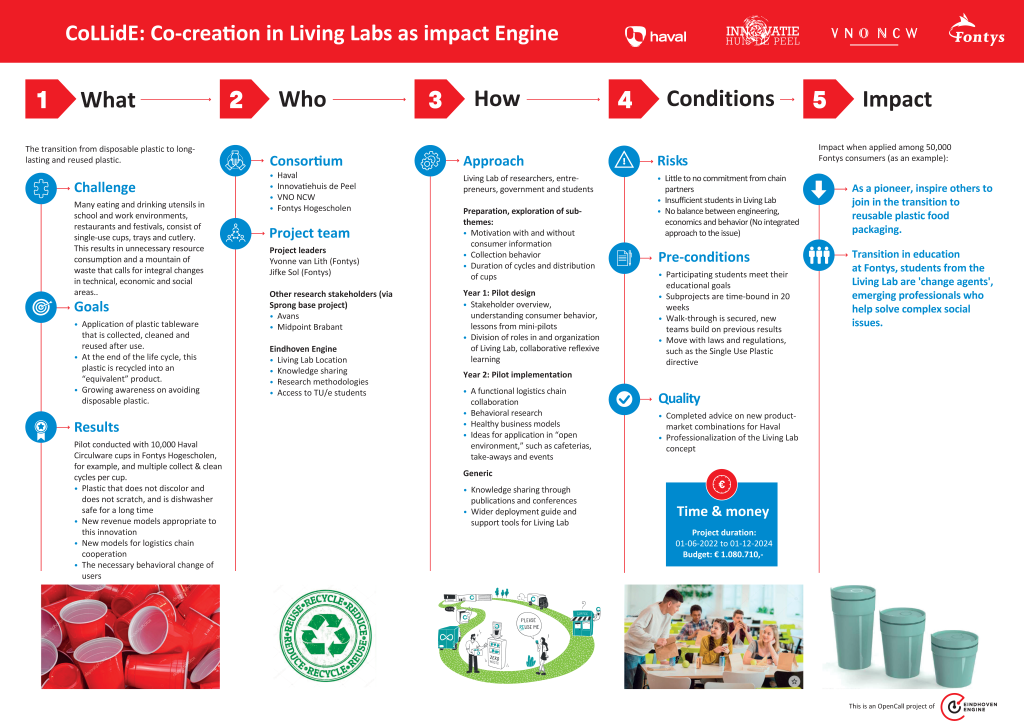

Co-creation in Living Labs as impact Engine. Living labs as catalysts for circular societal impact

The CoLLidE project focuses on the market introduction of reusable food packaging. The Circulware system, developed by project partner Haval, replaces single-use food packaging with reusable and recyclable, bio-based packaging and will be applied in a living lab in this project. This will enable the use of the new packaging to be investigated from a technical, economic and social perspective. In the living lab, entrepreneurs, students, researchers, public authorities and companies will collaborate and learn together. The living lab will act as a catalyst for circular societal impact and will also investigate how a behavioral change towards food packaging can be achieved.

Infographic

About the project

The concentration of nitrogen dioxide and particulate matter is still too high in the Netherlands according to WHO guideline values in 2021. In the Eindhoven region, several technical developments and research and innovation initiatives have been started in this field. As a result, a lot of information on population dynamics, such as commuting traffic and air pollution, is readily available. In DynaPopeX, this information is brought together for the first time and visualization techniques can be used to make connections to the sources of air pollution.

The combination of data, location and human movements in Eindhoven makes it possible to take tangible measures to reduce the exposure of people on the street to harmful particulate matter and limit possible harm to health.

Video

Ruben Goudriaan – Project Manager TNO & Rik Thijs – Councilor Municipality of Eindhoven

Partnership is essential in this project. The research institute TNO collaborates with the government, industry, neighboring municipalities, and the province of North Brabant. Together, we are working towards clean air for the residents of Eindhoven.

About the project

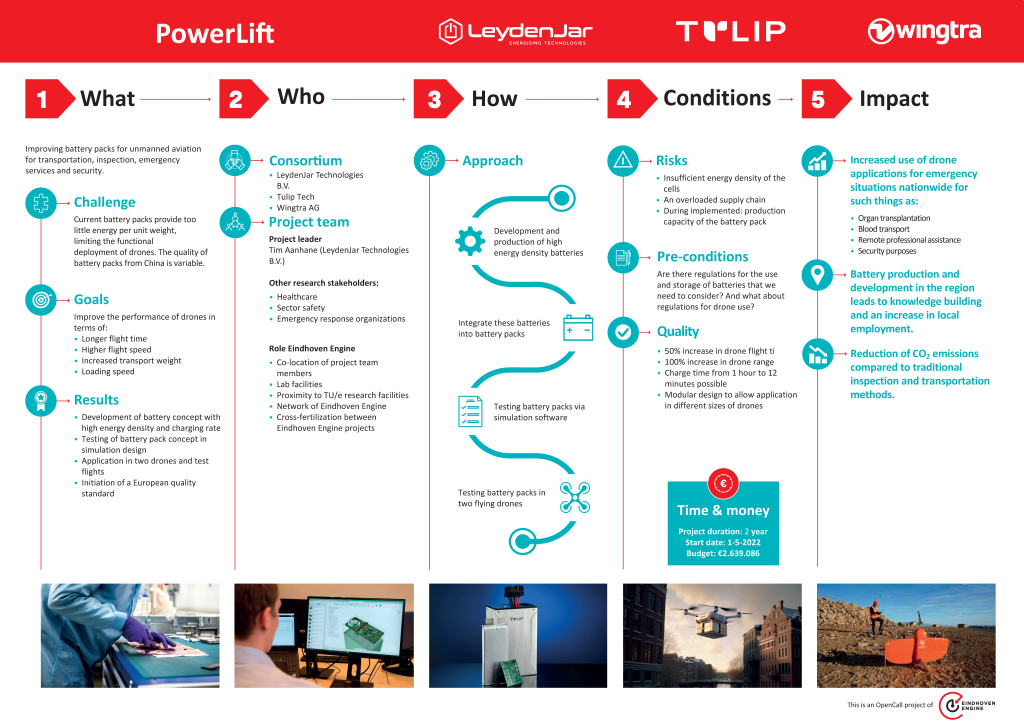

In the PowerLift innovation project, research is being done on a sustainable battery for the electric aviation industry (eFlight). This battery not only has a long lifetime but can store an extraordinary amount of energy and delivers a lot of energy when used. Within Eindhoven Engine, PowerLift will further develop this technology into a standardized platform for the production of customized eFlight batteries.

Video

Tim Aanhane – Leydenjar | Bernd Rietberg – Tulip Tech

Through our collaboration at Eindhoven Engine with Tulip Tech and Wingtra, we are creating a modular design that allows customizable battery capacity and power—whether it’s a compact pack or a robust one, tailored precisely to each drone’s requirements.

Bernd Rietberg – Tulip Tech | Haitham Khamis – Tulip Tech | Tim Aanhane – Leydenjar

In project PowerLift we develop battery systems for industrial drones. As a partner within this project Tulip Tech builds battery systems with the highest specific energy density in the world. That means that the batteries have two to three times more energy per kilogram.

Infographic

About the project

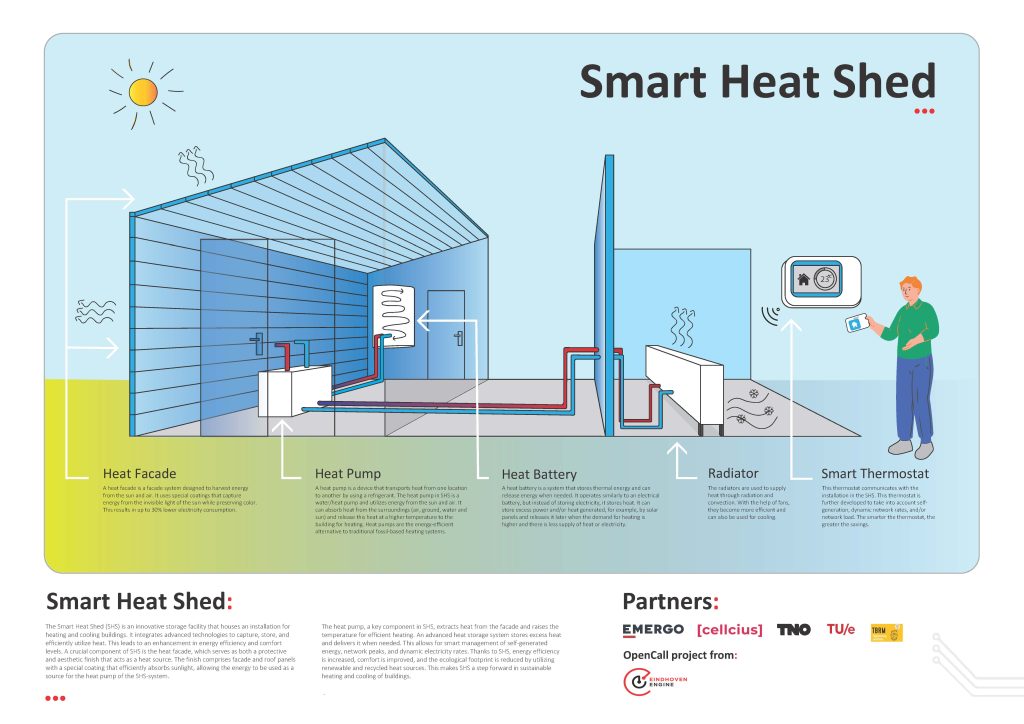

The Smart Heat Shed (smart heat storage) project addresses the rapid energy transition by combining two international breakthrough technologies, a heat façade and a heat battery. The heat facade (developed by TNO-Emergo spin-off Calosol) is an innovative, aesthetically versatile solar thermal facade collector, which effectively harvests solar energy at low outdoor temperatures. The heat battery (developed by the TNO-TU/e spin-off Cellcius) is the first completely loss-free heat storage solution. The latter is also 10x cheaper than electrical storage and much more compact than water or phase transition materials (PCM).

Infographic

More about the project

Smart shed powers buildings year-round

Media: ‘Slim schuurtje’ voorziet gebouwen het hele jaar door van energie

Interns join Smart Heat Shed and Low Literacy projects

About the project

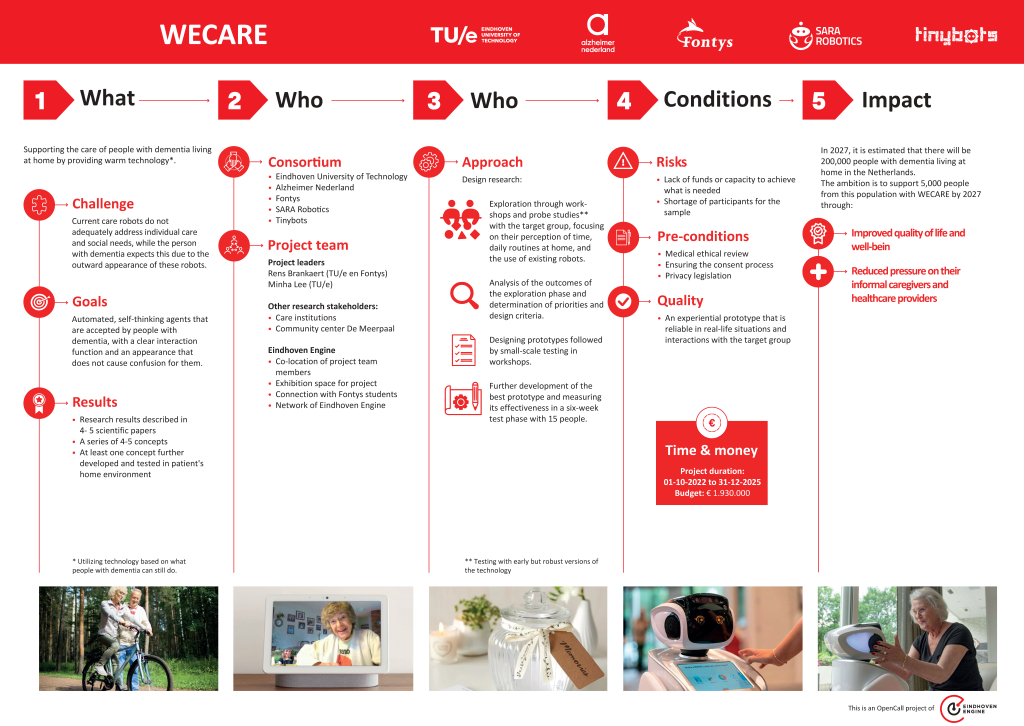

Currently, there are 55 million people worldwide with dementia. This number is expected to rise to 78 million by 2030 and 138 million by 2050 according to the WHO. There is currently no medical solution for dementia. In addition, there is a shortage of caregivers. This is putting the healthcare system under pressure. Technology should and can provide the support needed for dementia sufferers and their caregivers.

Warm technology

The WECARE project focuses on extending human care by applying the Warm Technology concept to interactive agents, such as chatbots and companion robots. Warm Technology ensures that this technology is made accessible and appropriate for the environment of people with dementia and their caregivers, thereby also taking this environment into account. In this project, work is being done to develop more advanced behaviors and representations in interactive agents.

Infographic