About the project

The project started with a feasibility study on market introduction. The mouth-nose mask is an innovative product that is made almost entirely (95%) from biological renewable raw materials: PLA with bio-PP for a filtering effect and recycled steel for the nose bridge. As the mouth-nose mask is 20-45% lighter, less raw materials are used.

The development and production of the new ProM mask will be more sustainable by using the knowledge and skills of previous in-house development and production processes combined with the knowledge and expertise of prominent Dutch scientific knowledge and training institutes.

Together, we aim for a sustainable future by making and keeping innovative, sustainable mouth-nose masks available for healthcare in the Netherlands and, where possible, the rest of Europe.

We have been able to produce a new affordable and sustainable FFP2 medical mask. These masks are ready to be tested and certified by the proper notified bodies in 2023 and may eventually be brought to the market.

This research is supported by Small Business Innovation Research (SBIR) of the Netherlands Enterprise Agency (RVO).

Other updates

Sustainable mouth/nose mask consortium successfully concluded

Media: Eindhoven Engine competes with cheap face masks from abroad

Accelerate by working together

Videos

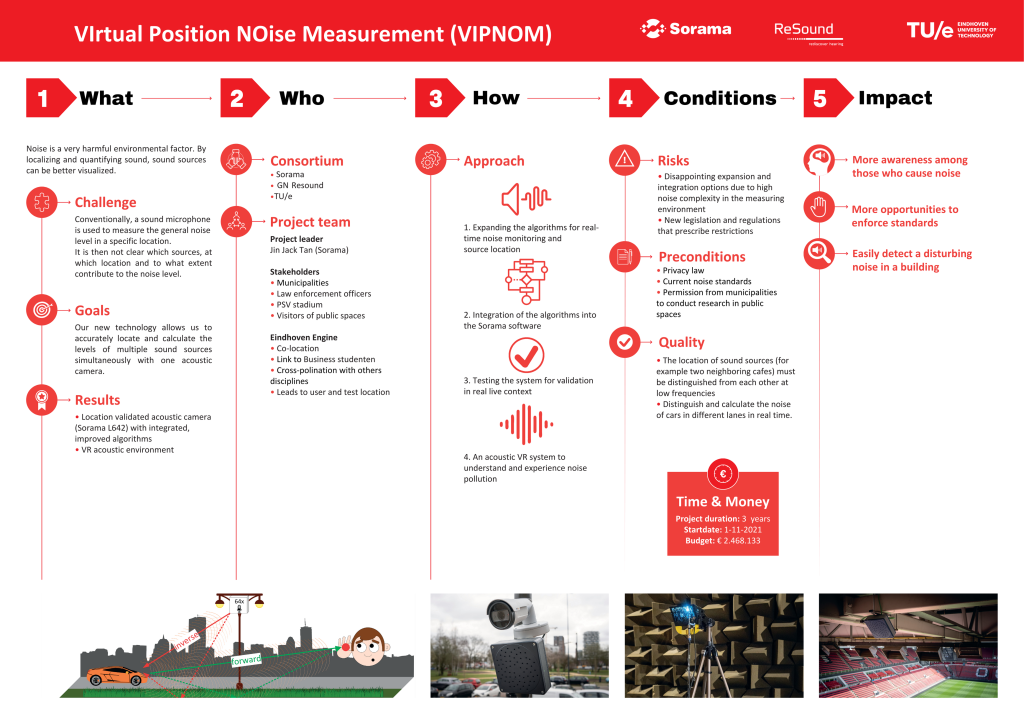

Jin Jack Tan – Project leader & Acoustics Team Lead Sorama

At Sorama, we make sound insightful and we intend to improve everybody’s live. We develop acoustic cameras to enable us to perform noise monitoring. Why? Because Jin Jack believes we all deserve to be able to live a life that is more quiet and more away from noise.

Infographic

More project info

NEON EE project: addressing societal challenges

The first pilot of the Business Model Innovation in an Exponential World course for the NEON project

Videos

The built environment is responsible for about 36% of the global energy demand. About 5-30% of the energy use of buildings is related to energy waste due to faults in heating, ventilation and air-conditioning systems. The goal is to develop a self-learning module that can monitor and diagnose climate systems in large buildings.

Rick Kramer – Project leader & Assistent Professor TU/e | Srinivasan Gopalan – PhD canditate TU/e

The goal is to develop a self-learning module that can monitor and diagnose climate systems in large buildings. Rick Kramer is the project leader of this project. Srinivasan is one of his PhD candidates who is focusing on developing a generic, robust and reliable fault detection and diagnosis tool

Petros Zimianitis – EngD trainee TU/e

Petros is focusing on the people within large buildings. He is doing research on the control and the functionality of a personalized control system, that people will be able to use in their office environment to tailor it according to their needs and preferences.

About the project

In this research, Eindhoven Engine and its partners will focus on the development of sustainable medical isolation gowns that can be used multiple times: the ProH I-gown. In addition, an investigation will take place into how the production capacity can be made (economically) scalable and flexible when necessary.

These sustainable medical isolation gowns can save six tons of CO2 per million gowns. If these isolation gowns are fully utilized during crisis situations, the result could be a saving of 0.2% of the total plastic waste stream in the Netherlands. In addition, ProH I-gowns stimulate the production of protective clothing in Europe.

The execution of this research consists of two phases. Eindhoven Engine, research organization TNO and manufacturer HAVEP will carry out a technical feasibility assessment in the first phase. A business case will also be set up. The gowns will be made of woven PET material with an environmentally friendly coating. Research will also be carried out into the durability and wearability of these gowns. In phase two of the project, the concrete industrialization will be worked out in detail.

In the first and second quarter of 2022, HAVEP started the production of the sustainable medical isolation gowns. The gowns were tested in the Reinier de Graaf Gasthuis with positive results. The Life Cycle Analyses (LCA) also had a positive outcome. Due to the rapidly changing market, among other things, we have currently frozen the further development of ProH I-gowns.

This research is supported by Small Business Innovation Research (SBIR) of the Netherlands Enterprise Agency (RVO).

More project info

Phase 2 of SBIR project on sustainable medical isolation gowns gets started

Accelerate by working together