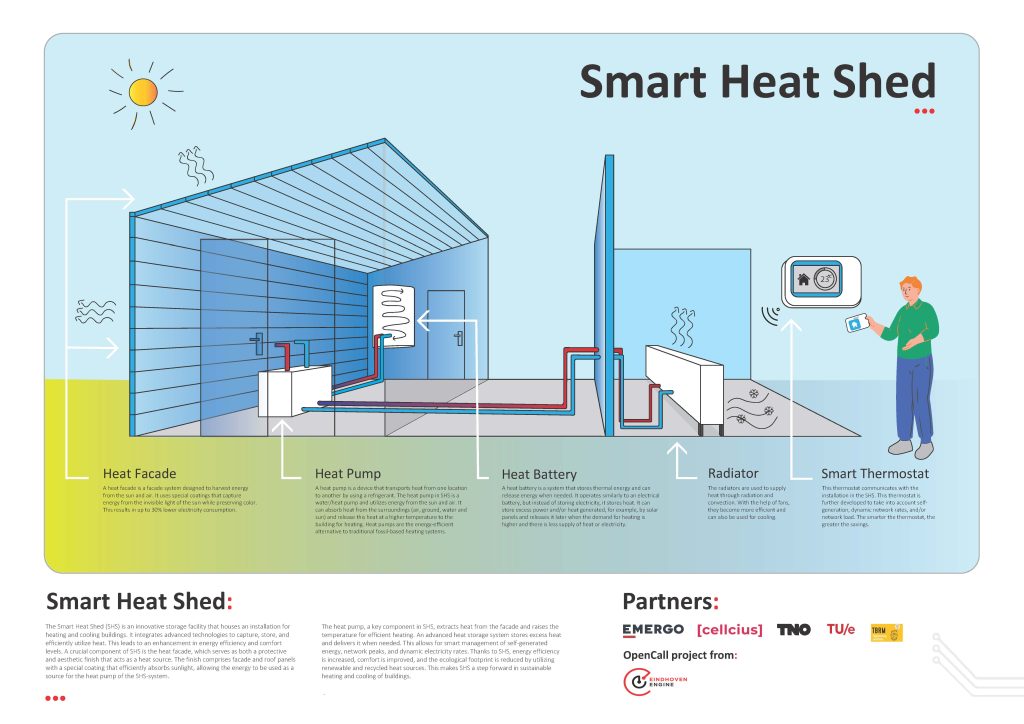

Infographic

More about the project

Smart shed powers buildings year-round

Media: ‘Slim schuurtje’ voorziet gebouwen het hele jaar door van energie

Interns join Smart Heat Shed and Low Literacy projects

Media: New innovation projects for Fontys in Eindhoven Engine

Fontys participates with two new innovation projects in Eindhoven Engine, the innovation accelerator of the Brainport region. A total of seven new innovation projects will start.

These projects in particular in the fields of energy, health and smart mobility will conduct research in the coming years with a total budget of nearly 17 million euros, to which Eindhoven Engine contributes a total of over 2.4 million euros. The investment for the Eindhoven Engine OpenCall 2022 comes from the Brainport Regio Deal.

The seven projects can bring their innovations to the market faster, as they continue their research within Eindhoven Engine, collaborate at Eindhoven Engine’s colocation on the TU/e campus and build the internal community together. Until 2025, the new projects have time to use the boost from Eindhoven Engine to further develop their innovations.

About the project

In this research, Eindhoven Engine and its partners will focus on the development of sustainable medical isolation gowns that can be used multiple times: the ProH I-gown. In addition, an investigation will take place into how the production capacity can be made (economically) scalable and flexible when necessary.

These sustainable medical isolation gowns can save six tons of CO2 per million gowns. If these isolation gowns are fully utilized during crisis situations, the result could be a saving of 0.2% of the total plastic waste stream in the Netherlands. In addition, ProH I-gowns stimulate the production of protective clothing in Europe.

The execution of this research consists of two phases. Eindhoven Engine, research organization TNO and manufacturer HAVEP will carry out a technical feasibility assessment in the first phase. A business case will also be set up. The gowns will be made of woven PET material with an environmentally friendly coating. Research will also be carried out into the durability and wearability of these gowns. In phase two of the project, the concrete industrialization will be worked out in detail.

In the first and second quarter of 2022, HAVEP started the production of the sustainable medical isolation gowns. The gowns were tested in the Reinier de Graaf Gasthuis with positive results. The Life Cycle Analyses (LCA) also had a positive outcome. Due to the rapidly changing market, among other things, we have currently frozen the further development of ProH I-gowns.

This research is supported by Small Business Innovation Research (SBIR) of the Netherlands Enterprise Agency (RVO).

More project info

Phase 2 of SBIR project on sustainable medical isolation gowns gets started

Accelerate by working together